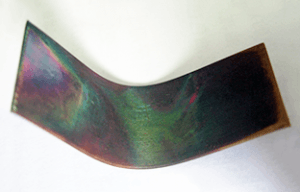

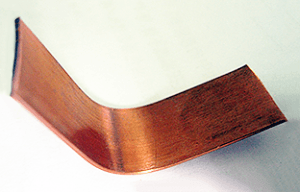

Corrosive Sulfur can be found in transformer oil and its presence can cause transformers to prematurely fail. Dibenzyl Disulfide (DBDS) is a sulfur compound known to react with the copper windings, creating byproducts that degrade the insulation, leading to eventual failure. This can occur at levels as low as 3 ppm DBDS.

PSS has a unique process that destroys the presence of DBDS and halts the corrosion within the transformer.

The PSS process is designed for voltage classes 230 kV and below, a major advantage over other processing methods. Our process is less expensive and more effective than purchasing new oil, and can be performed while the transformer is energized—requiring no costly outages. Rather than just masking the problem, the PSS process destroys the source of the corrosive sulfur, permanently removing the DBDS.